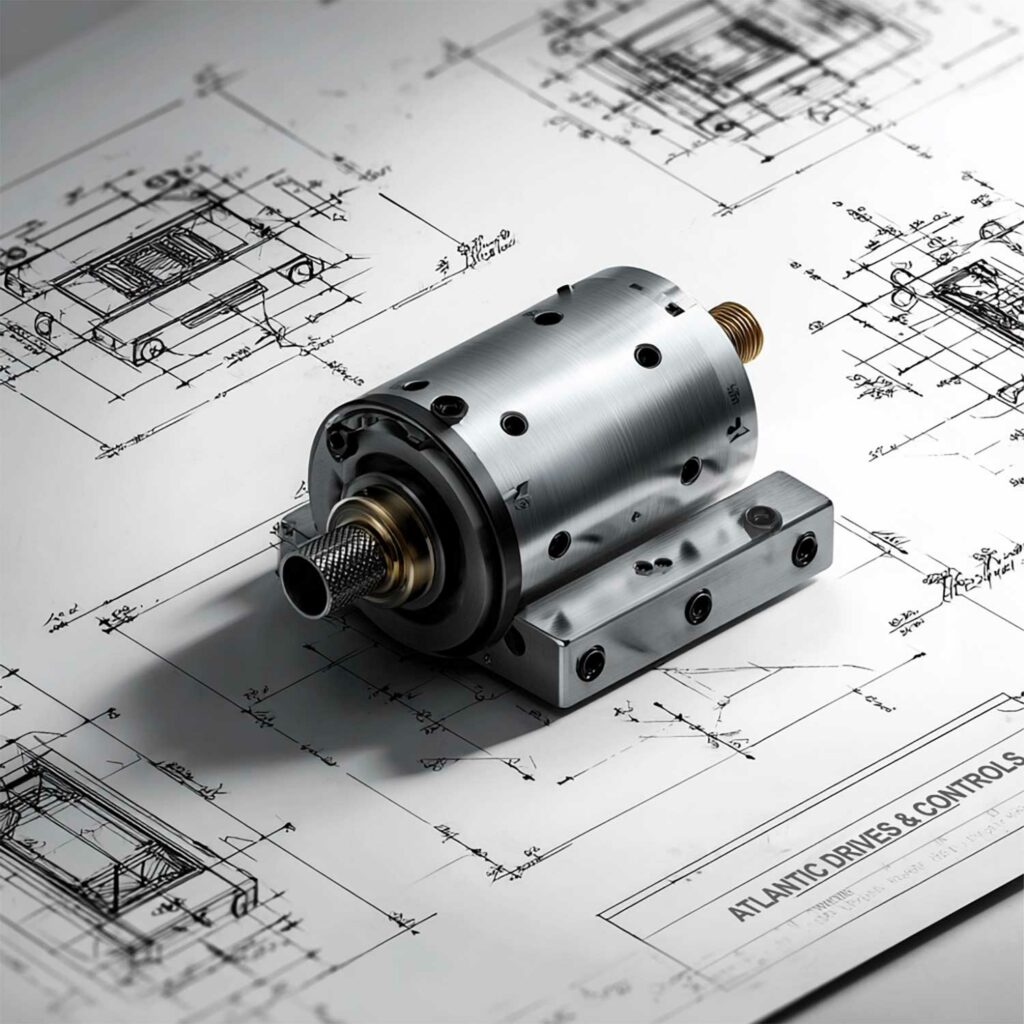

CAD Design & Engineering Services

Engineering & Automation Solutions

From precision measurement to CAD design and manufacturing, we deliver comprehensive engineering solutions that bring your concepts to life.

Overview

Our Engineering-Driven Solutions

Engineering-Driven Precision Measurement & Automation Controls

Atlantic Drives & Controls uses advanced Coordinate Measuring Machines (CMM) to capture precise dimensional data from your automation control components with exceptional accuracy, ensuring every part performs at optimal specifications.

Whether you need new custom parts manufactured or existing automation control systems serviced and repaired, our integrated approach combines in-house CAD engineering, precision machining, and metrology expertise.

Our comprehensive measurement and engineering capabilities mean we can quickly diagnose issues, design replacement components, machine parts on-site, and have your automation systems running again—all without waiting for outside vendors.

By maintaining both manufacturing and servicing capabilities under one roof, we reduce downtime, cut costs, and ensure your automation controls receive expert attention from the engineers who understand your systems.

CAD Design & Engineering Services

Atlantic Drives & Controls’ experienced engineering team transforms your concepts and requirements into production-ready 3D CAD models and detailed technical drawings.

We work with industry-standard design software to optimize your designs for manufacturability, cost-effectiveness, and performance—with specialized expertise in drives, controls, and industrial systems engineering.

Every drawing package includes comprehensive engineering documentation, material specifications, and manufacturing notes that guide your fabrication and assembly teams through project requirements. Whether you need reverse engineering from existing equipment or forward design from your specifications, our CAD expertise bridges the gap between your vision and manufacturing reality.

Integrated Manufacturing Solutions

- Complete CAD-to-part manufacturing from digital design to finished component

- CNC machining and precision fabrication capabilities for complex geometries

- In-house engineering expertise that optimizes designs for production efficiency

- Quality control integration with CMM verification at critical manufacturing stages

- Rapid prototyping and iterative design refinement based on physical testing

- Full-service project management coordinating design, fabrication, and quality checkpoints

Our Process

For complex projects, our engineering team can often begin the initial phase within 24-48 hours

- Initial consultation and engineering requirements assessment

- Precision measurement using advanced CMM technology

- CAD design and technical drawing development

- Design optimization and manufacturability review

- Manufacturing, quality control, and final inspection

- Delivery, documentation, and ongoing technical support

Why Chose us

Key Advantages

- Specialized drives and controls expertise

- Integrated CAD-to-part capability

- Precision CMM verification included

- Accelerated project timelines

- Experienced engineering team

- Comprehensive technical documentation